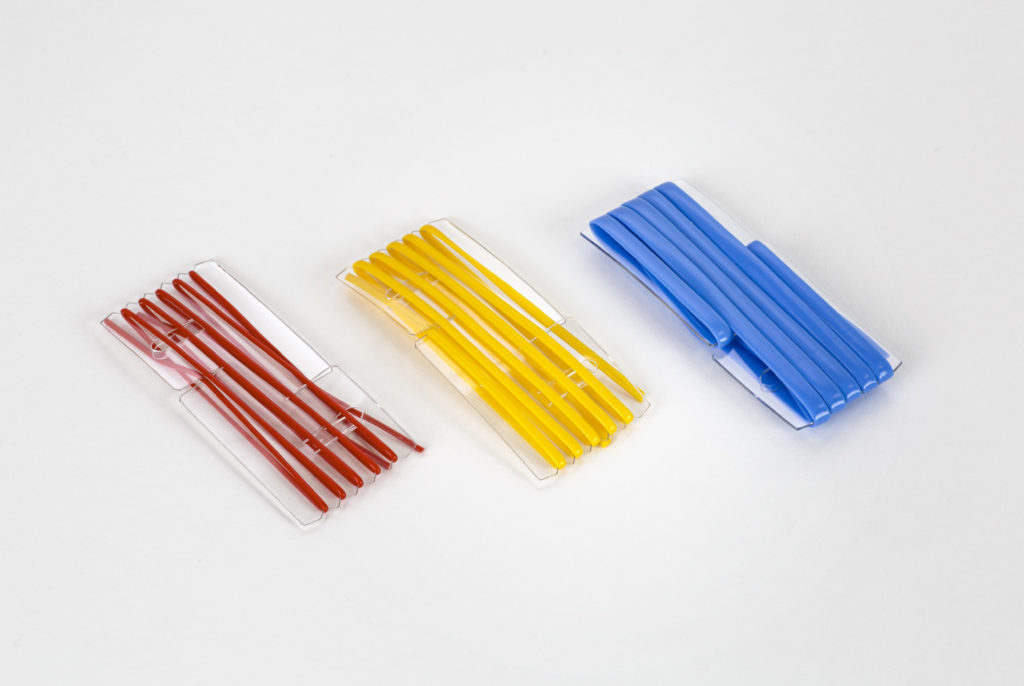

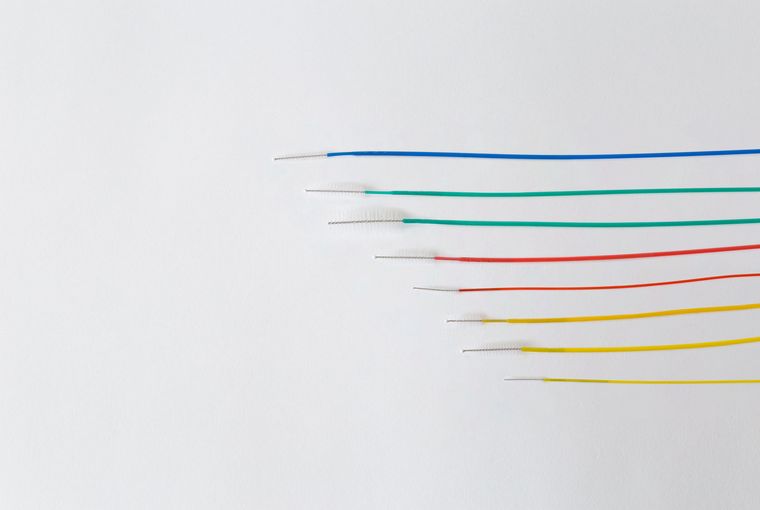

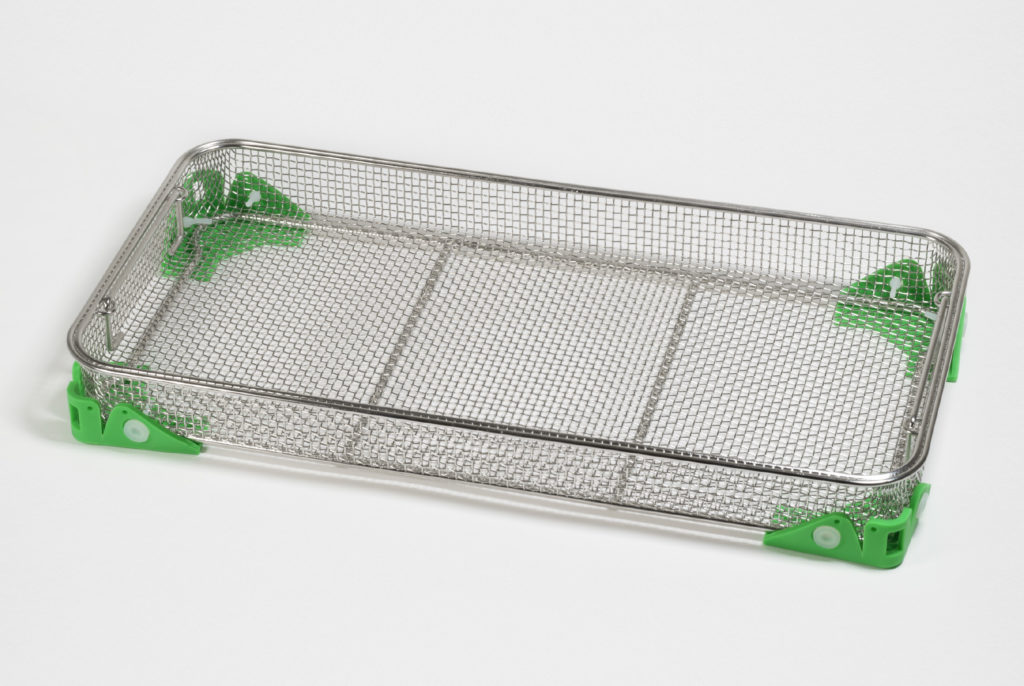

Stericlin® highline instrument protection caps

Protection against damage for points and edges

Stericlin® Highline instrument protection caps are available in different versions, and are specially designed for instrument protection. The easy-to-use protective caps, are protecting the tips and edges of the instruments from damage during sterilisation and transport. In addition, highline protective caps help to prevent damage to the sterile barrier system (e.g. transparent packaging) and cut and stab injuries to employees.

In order to increase patient safety, we deliberately refrain from punching holes in stericlin® Highline instrument protection caps, as these cannot be produced completely without burrs according to current state-of-the-art technology. Especially when using sharp-edged instruments, it cannot be ruled out that particles become separated from the holes in the protective cap. In order to be able to ensure that the sterilisation medium flows around the instruments very well, even without perforating the protective cap, the protective caps are equipped with internal knobs. These prevent the protective caps from being too tight and fully adhered on the instruments and subsequently reliably enable successful sterilisation.

All versions are suitable for steam sterilisation.

Why our protection caps are not perforated?

Contamination due to cutting residues

During internal inspections, it became apparent that in the case of perforated protective caps, which represent the most common product group on the market, production surpluses (burrs) are visible in the punched holes. This is mainly due to the punching process, which as a rule cannot be carried out completely without residues. These tiny particles/residues bear the risk of falling off during the use of the protective cap and instrument, remaining on the instrument and, in the worst case, getting into the patient during an operation or wound treatment.

Basically, punched holes give the impression that holes ensure a safe sterilisation result. The impression can arise that steam flows through the holes under the cap or onto the instrument surface and ensures a safe sterilisation result. This is only partial correct!

Only the correct selection of the protective cap size gives the possibility to achieve sufficient steam circulation around the instrument. gives the possibility to achieve sufficient steam circulation around the instrument. In reality, this can lead to perforated protective caps sitting too lightly on the instrument and therefore falling off during the process.

To avoid these risks, we have turned to new designs and manufacturing processes and have chosen protective caps with inner nubs because of their clear advantages. The nub protection cap reduces the risk of choosing too small cap sizes, as even with a tighter fitting nub protection cap, the nubs minimize the contact area which allows steam to still flow around the instrument. We have proven the sterilisation success through sterilisation validations by an independent laboratory.

| Article No. | Description | Size in mm | Colour (translucent) | Pack (pcs.) |

| 3FSZB730456 | Round cap | 1,6 × 19 | white | 100 |

| 3FSZB730420 | Round cap | 1,6 × 19 | clear | 100 |

| 3FSZB730458 | Round cap | 2 × 19 | blue | 100 |

| 3FSZB730422 | Round cap | 2 × 19 | clear | 100 |

| 3FSZB730460 | Round cap | 2,8 × 19 | green | 100 |

| 3FSZB730424 | Round cap | 2,8 × 19 | clear | 100 |

| 3FSZB730462 | Round cap | 3,2 × 25,4 | red | 100 |

| 3FSZB730426 | Round cap | 3,2 × 25,4 | clear | 100 |

| 3FSZB730464 | Round cap | 5 × 25 | yellow | 100 |

| 3FSZB730428 | Round cap | 5 × 25 | clear | 100 |

| 3FSZB730411 | Round cap | 10 × 19 | violet | 100 |

| 3FSZB730413 | Round cap | 10 × 19 | clear | 100 |

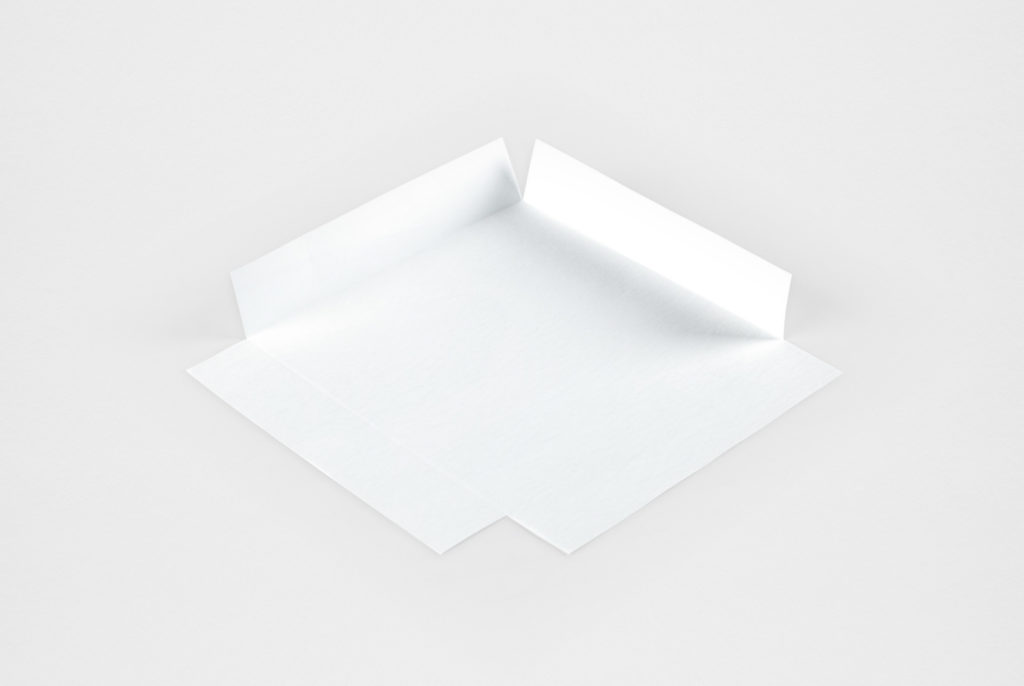

| 3FSZB730452 | Flat cap | 6,4 × 19 | clear | 50 |

| 3FSZB730454 | Flat cap | 2 × 9 × 25 | clear | 100 |

| 3FSZB730444 | Flat cap | 2 × 9 × 25 | orange | 100 |

| 3FSZB730440 | Flat cap | 12,7 × 25 | clear | 50 |

| 3FSZB730468 | Flat cap | 2 × 16 × 25 | brown | 100 |

| 3FSZB730466 | Flat cap | 2 × 16 × 25 | clear | 100 |

| 3FSZB730450 | Flat cap | 19 × 25,4 | clear | 50 |

| 3FSZB730446 | Flat cap | 3 × 25 × 25 | clear | 100 |

| 3FSZB730448 | Flat cap | 3 × 25 × 25 | black | 100 |

| 3FSZB730441 | Flat cap | 32 × 32 | clear | 50 |

| 3FSZB730443 | Flat cap | 38 × 38 | clear | 50 |

| 3FSZB730445 | Flat cap | 32 × 44,5 | clear | 50 |

| 3FSZB730470 | Pointed cap | Ø: 2 – 3 / length: 38 | white | 70 |

| 3FSZB730472 | Pointed cap | Ø: 3 – 4 / length: 38 | blue | 70 |

| 3FSZB730474 | Pointed cap | Ø: 4 – 5 / length: 38 | green | 70 |

| 3FSZB730476 | Pointed cap | Ø: 5 – 6 / length: 38 | red | 70 |

| 3FSZB730477 | Pointed cap | Ø: 6 – 7 / length: 38 | yellow | 70 |

| 3FSZB730478 | Pointed cap | Ø: 7 – 8 / length: 38 | violet | 70 |

| 3FSZB730480 | Pointed cap | Ø: 2 – 3 / length: 51 | white | 70 |

| 3FSZB730482 | Pointed cap | Ø: 3 – 4 / length: 51 | blue | 70 |

| 3FSZB730483 | Pointed cap | Ø: 4 – 5 / length: 51 | green | 70 |

| 3FSZB730484 | Pointed cap | Ø: 5 – 6 / length: 51 | red | 70 |

| 3FSZB730485 | Pointed cap | Ø: 6 – 7 / length: 51 | yellow | 70 |

| 3FSZB730487 | Pointed cap | Ø: 7 – 8 / length: 51 | violet | 70 |

| 3FSZB730429 | Twin cap | 1,6 × 19 | white | 50 |

| 3FSZB730431 | Twin cap | 2 × 19 | blue | 50 |

| 3FSZB730430 | Twin cap | 2,8 × 19 | green | 50 |

| 3FSZB730432 | Twin cap | 3,2 × 25 | red | 50 |

| 3FSZB730434 | Twin cap | 5 × 25 | yellow | 50 |

| 3FSZB730435 | Twin cap | 2 × 9 × 25 | orange | 50 |

| 3FSZB730486 | Retractor cap | 13 × 25 | violet | 50 |

| 3FSZB730488 | Retractor cap | 13 × 25 | clear | 50 |

| 3FSZB730490 | Retractor cap | 13 × 32 | clear | 50 |