BMS 1200 Batch Monitoring System

Batch monitoring system according to requirements of DIN EN 867-5

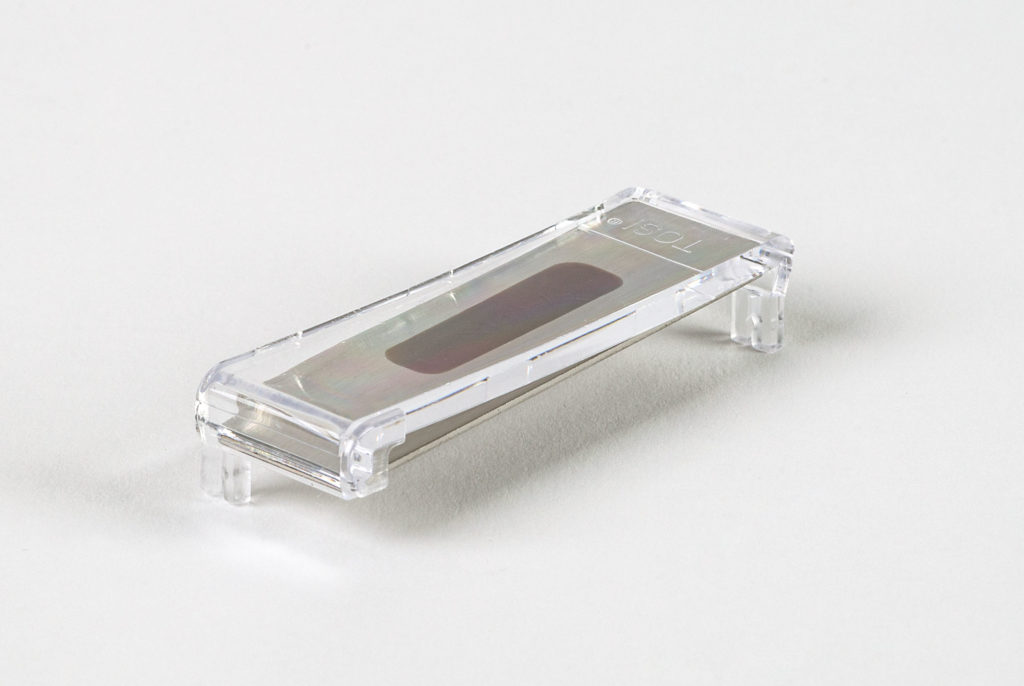

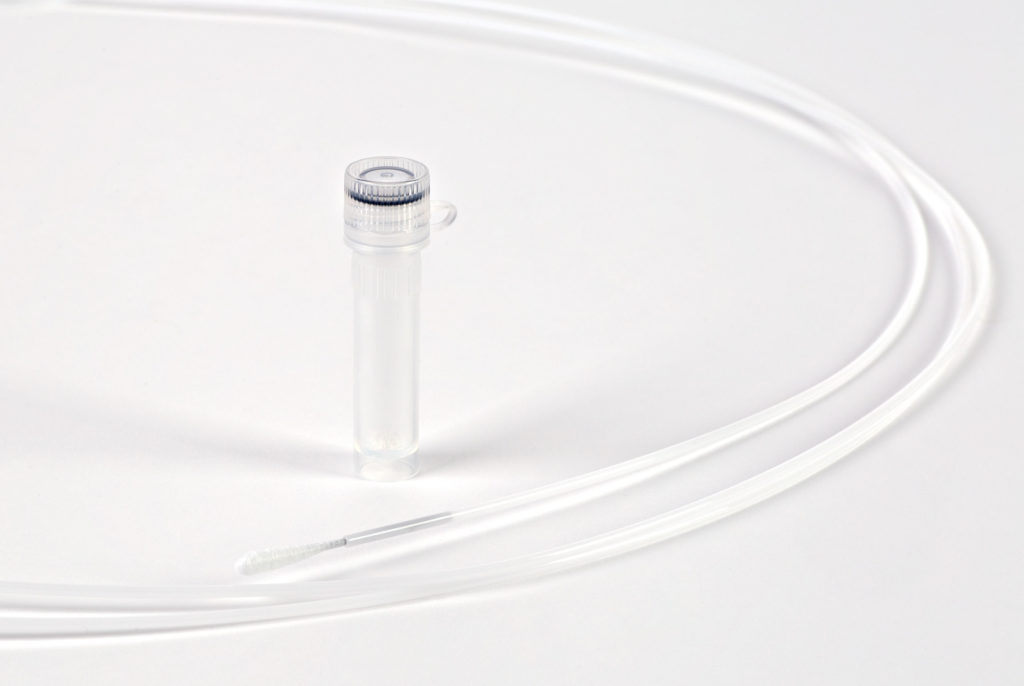

Our stericlin® Batch Monitoring System meets the requirements of DIN EN 867-5 and is specially designed for batch control of the sterilisation load. The process challenge device (PCD) made of aluminium simulates hard to sterilise hollow instruments. The so-called “helix” is located inside and at the end the chemical indicator is placed in a screw cap made of plastic. The PCD may be reused.

The handling of the stericlin® Batch Monitoring System is easy as well as time and space efficient:

- Place indicator strip in the capsule

- Screw the capsule on the PCD

- Run sterilisation programme

- Remove the test strip

- Check result

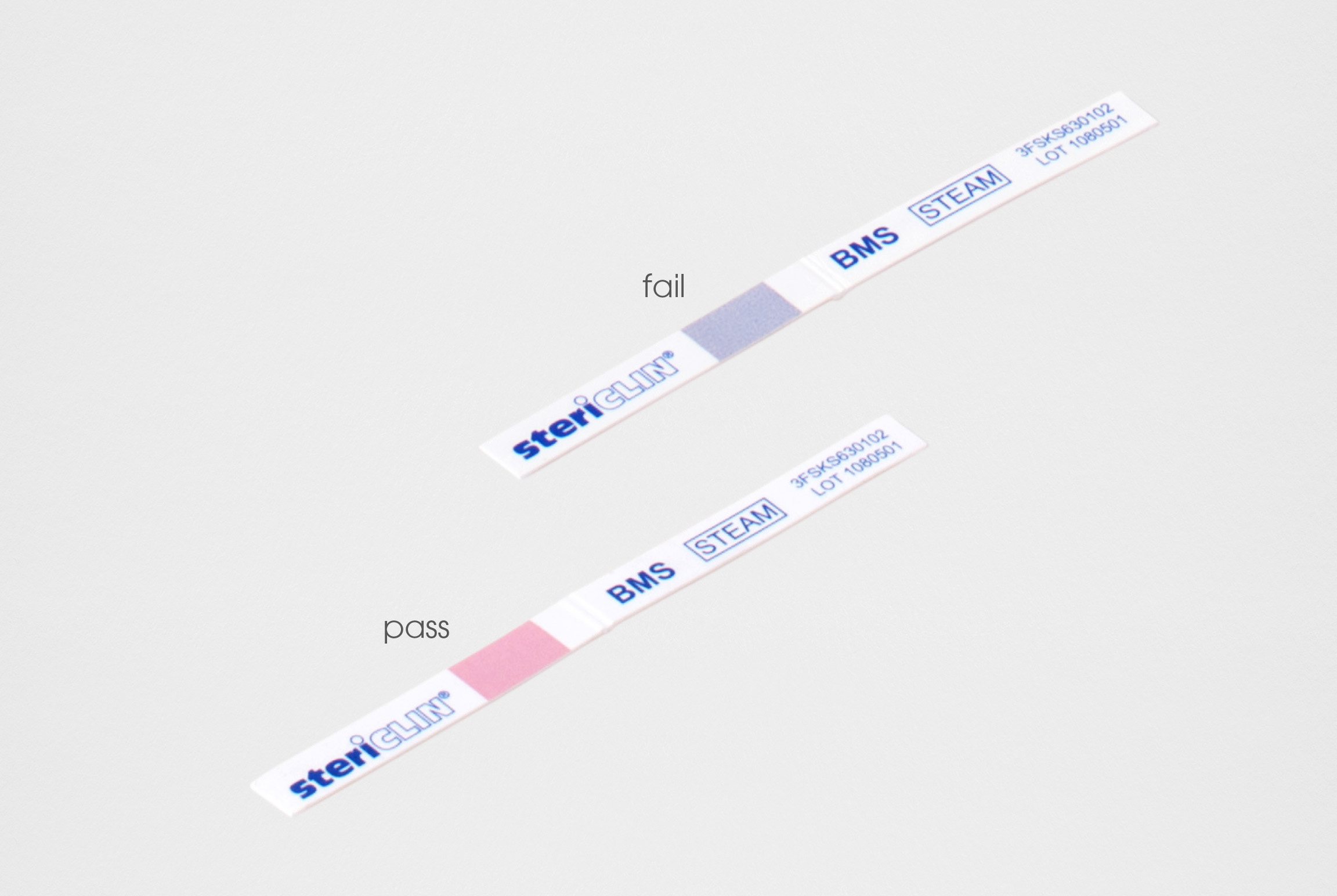

With full steam penetration, the indicator changes colour from blue to pink, incomplete colour change indicates a malfunction of the steriliser.

Stericlin® indicators contain no heavy metals or toxins. After the initial colour change, the colour of the indicator no longer changes. This gives you completely secure documentation.

The use of batch control systems to monitor steam penetration is recommended by the Commission for Hospital Hygiene and Infection Prevention at the Robert Koch Institute (RKI), the Federal Institute for Drugs and Medical Devices (BfArM), the German Society for Hospital Hygiene and health authorities.

| Article No. | Description | Pack (pcs.) |

| 3FSKS630106 | Starter Kit: 1 PCD, 2 capsules, 250 indicator strips | 1 |

| 3FSKS630102 | Indicator strips (incl. 1 capsule), size: 76,5 × 5,5 mm | 250 |